| Brands |

Sample img |

Product |

Applications |

Contact |

|

|

ZEISS BOSELLO

X-ray Inspection Systems |

Real-time inspection for aluminum casting, steel casting, plastics, ceramics, special aluminum alloy |

|

|

|

AIM

Non-contact thickness measurement system |

The main products include online/offline coating thickness measurement, and customized solutions can be provided。 |

|

|

|

BTGLABS

Portable surface analyst |

Equips manufacturers with the insight to reduce scrap, recalls and rework caused by adhesion failure. |

|

|

|

DAKOTA

Ultrasonic Thickness Gauge |

Measure the thickness of steel, cast iron, plastic, fiberglass, glass, aluminum, copper and other materials. |

|

|

|

FOMA

Industrial X-Ray Film |

Supplied as darkroom packing or as daylight packing in accordance with ISO 5655 standard. |

|

|

|

GEARTEC

Unique And High Quality Gear Inspection Machines |

Single and double flank gear inspection machine for internal gear, spur gear, helical gear |

|

|

|

GRAETZ

Radiation Inspection Instrument |

Radiation detector |

|

|

|

ICM

Portable X-Ray Generator |

Ultralight and efficient constant potential portable X-Ray generators and digital X-Ray scanners for security (EOD) and NDT applications |

|

|

|

iNOEX

Plastic molding related testing, quality control, raw material control equipment |

Pressure and gas pipes, hot water pipe, sewage pipe, corrugated pipe, tubes, film, cable, profile, blow moulding |

|

|

|

IT CONCEPTS

Flexible endoscope |

Can measure HD image quality hose endoscopes in 3D. |

|

|

|

LEONARDO

Automatic inspection equipment |

Helium leak detector/Full-size automatic inspection/fullyautomated inspection of rims and tires. |

|

|

|

NAWOO

Penetrant Solvant |

Pipe flaw, aerospace, automotive, casting and other industries |

|

|

|

NDT SYSTEMS

Ultrasonic gauges |

Bond testing,thickness measurement, corrosion inspection, weld inspection, flaw detection, composite inspection, automotive sonic testing, educational |

|

|

|

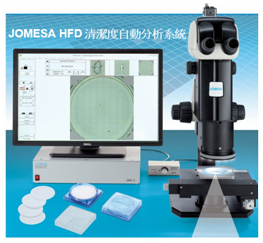

JOMESA

Automatic optical particle analysismicroscope |

Advanced technical products in automotive, aircraft and medical industries require clean components.Industrials standards like VDA Vol. 19 and ISO 16232 are the frameworks for cleanliness analysis. |

|

|

|

SCHOLLY

Endoscopes and Visualization Systems |

Observing the internal structure of engine and the inner wall of joint parts, internal corrosion of pipeline in petrochemical industry |

|

Source |

|

Source

IR-192

Co-60 |

Industrial gamma radiography equipment and radioactive sources |

|

|

|

STRESSTECH

Residual Stresses Testing |

Tests such as gears, bearings, camshaft, crankshaft, piston pins and other grinding process control, heat treatment process control, defects and residual stress |

|

|

|

THE MODAL SHOP

Resonant Acoustic Inspection System |

Structural vibration and acoustic sensing systems in engineering application |

|

|

|

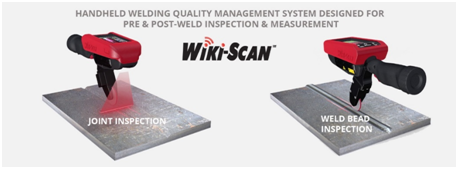

WIKI-SCAN

Portable welding inspection |

Handheld welding quality management system for tank and vessel, power generation, petroleum, tube and pipe, off-road, general industries, |

|