KINGYOUP Laser Debonding System KINGYOUP Sputtering System

Laser Debonding System for Temporary Bonding

Video

- High throughput

- The laser minimizes the cost of operation and maintenance

- Fast release from low power laser

- Full absorption by the coating layer without defect

- Minimum de-bonding stress

- Special release layer

- More adhesive options

Standard Product(s)

LD- Semi Automatic 200/300● Equipment Dimension: 1,600mm(W)*1,200mm(D)*2,430mm(H)

● Max. Scan Area: 470mm*470mm (4” /8” /12” wafer compatible)

● Scan Time:

1. 4”: 15 sec/wafer

2. 8”: 35 sec/wafer

3. 12”: 70 sec/wafer

LD- Automatic 200/300

● Equipment Dimension: 2,660mm(W)*2,800.5mm(D)*2,087mm(H)

● Max. Scan Area: 470mm*470mm (4” /8” /12” wafer compatible)

● WPH

1. 4”: 55 wafers/hour

2. 8”: 42 wafers/hour

3. 12”: 30 wafers/hour

Applications

- 2.5D/3D IC TSV

- Chip on Wafer on Substrate (CoWoS)

- Fan Out Wafer Level Package (FOWLP)

- Glass Interposer

- CIS BSI

- III V, RF Compound

- Vertical LED

- Flexible Film Substrate Handling

- Thin Glass Handling

- Panelized TOL

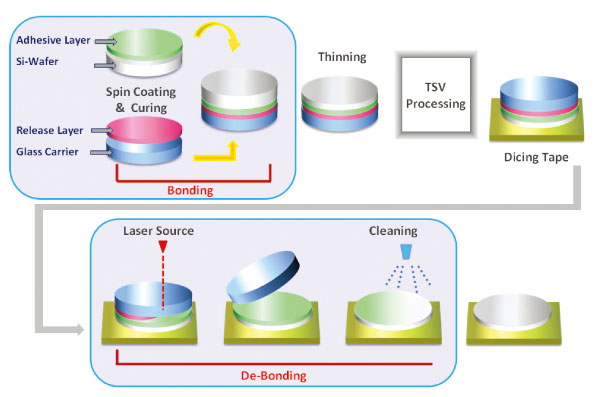

De-Bonding Process Flow